Category: Batch homogenizer

Model:KRH-F

Feature: High-shear homogenizer circulate to work with a tank, kettle or vessel. The rotation speed is variable, user can can control/adjust rpm freely

With high shearing rotor & stator workhead.

The high linear velocity and strong kinetic energy put the materials under comprehensive action.

With strong shearing, centrifugal extrusion, and mixing effect.

The solid-phase, liquid-phase and gas-phase will promptly dispersed and homogenized.

The homogenizer mixer circulates to work with a vessel or tank, and finally achieves the high quality products in short time.

• Whole machine is mounted on vessel, reactor or tank's top.

• The emulsifying rotor/stator workhead immerges into materials to work.

• Claw shaped workhead with double-direction suction.

• All contacting parts are made of stainless-steel.

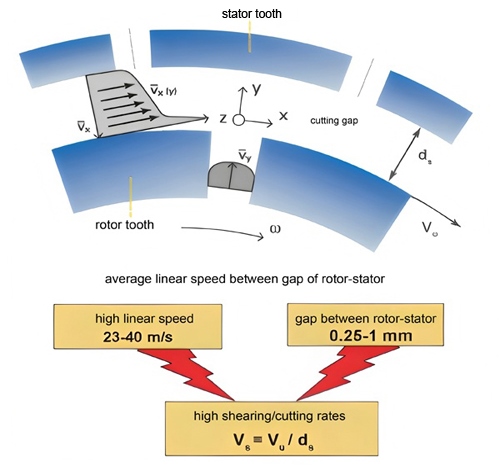

• Workhead has good gap fitness and high tip speed ensure excellent emulsifying and homogenizing.

• All components are processed by the CNC machine.

• Whole machine is easy to operate.

• This model is widely applicable for industrial production.

The homogenizer is consisted of rotor and stator workhead.

Under the centrifugal force and mechnical force generated by the high-speed rotor, the stator will put materials under comprehensive action such as strong shearing, centrifugal extrusion, crashing, hydraulic friction etc.

And the solid phase, liquid phase and gas phase which is insoluble at beginning will prompt evenly dispersed and emulsified with various additives.

After high-frequency circulation, stable materials with high quality are obtained in a short time.

The high shear emulsifying mixer will be installed on the top of a vessel, pot, reactor or tank.

With different power models for selection.

| Model | Capacity(L) | Power(kw) | Rotational Speed (rpm) |

| KRH –F-4 | ≤400 | 4 | 0-2880 |

| KRH –F-7.5 | ≤800 | 7.5 | 0-2880 |

| KRH –F-11 | ≤1000 | 11 | 0-2880 |

| KRH –F-15 | ≤1200 | 15 | 0-1440 |

| KRH –F-22 | ≤1800 | 22 | 0-1440 |

| KRH –F-30 | ≤2500 | 30 | 0-1440 |

| KRH –F-37 | ≤3000 | 37 | 0-1440 |

| KRH –F-45 | ≤4000 | 45 | 0-1440 |

| KRH –F-55 | ≤5000 | 55 | 0-1440 |

| KRH –F-75 | ≤6000 | 75 | 0-1440 |

Note:

* The processing capacity in the table is determined with " water " as the medium. Selection should be based on detailed calculations considering parameters such as the product's viscosity and specific gravity.

* If the conditions involve high temperature, high pressure, flammability, explosiveness, corrosivity, etc., detailed data must be provided for customized selection and design.

* This table does not include all products. For more information, please contact our sales engineers.

Material viscosity: <=100,000 cps

Production Capacity: 0L-12,000L

Applied materials: suitable for liquid or liquid-phase's high speed stirring, dissolving and scattering in the field of coating, paint, dye, printing ink, paint, cosmetics, resin, adhesive, latex, pharmaceutical, oil, powder, etc.