Category: Batch homogenizer

Model:KRH Series

Feature: High-shear rotor-stator head, with different style heads for selection. The working ways with the lifting up & stationary on vessel types

This model is also called " high-shear emulsifying mixer ", it is vertical suspension style workings.

Its workhead is high shear rotor-stator workheads structure.

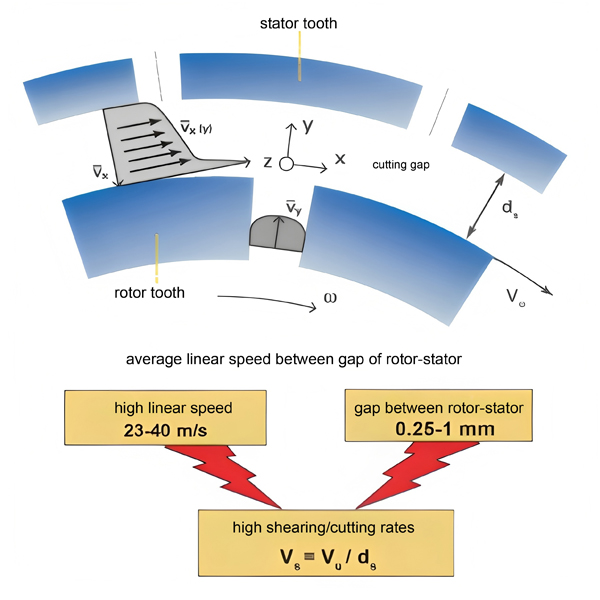

The workhead will generate high frequency mechanical action.

The products will be under strong emulsification, dispersion & mixing.

This model has the lifting up & falling down function.

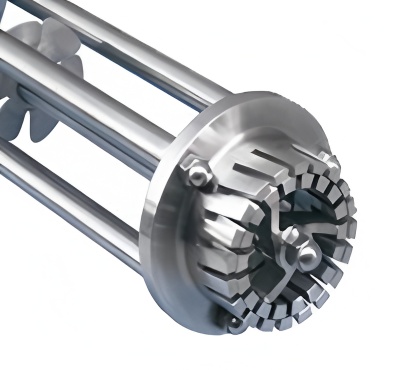

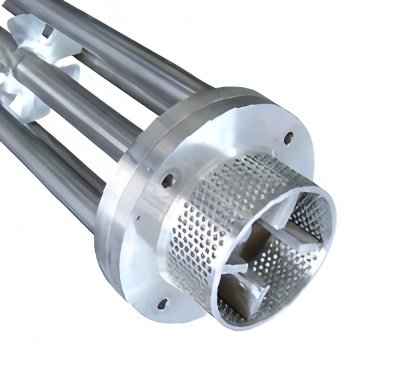

• Claw shaped workhead (Dual direction suction) is highly precised foundry.

• Good gap fitness and high tip speed ensure excellent emulsifying and homogenizing.

• All components are processed by CNC machine.

• With dynamic and static balance test for main shaft.

• Whole machine will ensure the stable&safe operation.

• This model can have the lifting up/lowering function.

• With below different style shear head for optional.

Sawtooth type Large Round hole type Screen hole type

For fine emulsions For high viscous products For middle or low viscosity

It is consisted of rotor and stator workheads.

Under the centrifugal force and hydraulic force generated by the high-speed rotor, the stator will put materials under comprehensive action such as strong shearing, centrifugal extrusion, crashing, hydraulic friction etc.

And the solid phase, liquid phase and gas phase which is insoluble at beginning will prompt evenly dispersed and emulsified with various additives.

After high-frequency circulation, stable materials with high quality are obtained in a short time.

User can select the lifting up function, so mixing workhead can lift up when works well.

| Model | Capacity(L) | Power(kw) | Speed(rpm) | Lifting stroke(mm) | Lifting power(kw) |

| KRH-1.1 | ≤100 | 1.1 | 0~2900 | 500 | 0.55 |

| KRH-2.2 | ≤200 | 2.2 | 0~3000 | 600 | 0.55 |

| KRH-4 | ≤400 | 4 | 0~3000 | 700 | 0.75 |

| KRH-11 | ≤800 | 11 | 0~3000 | 800 | 0.75 |

| KRH-15 | ≤1000 | 15 | 0~1450 | 900 | 1.1 |

| KRH-22 | ≤2000 | 22 | 0~1450 | 1000 | 1.1 |

| KRH-30 | ≤2500 | 30 | 0~1450 | 1100 | 1.5 |

| KRH-37 | ≤3000 | 37 | 0~1450 | 1200 | 1.5 |

| KRH-45 | ≤4000 | 45 | 0~1450 | 1300 | 1.5 |

| KRH-55 | ≤5000 | 55 | 0~1450 | 1500 | 2.2 |

| KRH-75 | ≤6000 | 75 | 0~1450 | 1600 | 2.2 |

| KRH-90 | ≤7000 | 90 | 0~1450 | 1800 | 3 |

Remarks:

* The above listed max. capacity is calculated according to water as medium. Model selection should depend on the comprehensive factors, such as materials' viscosity, gravity etc.

* If works under special environment such as high temperature, high pressure, explosive, combustible, corrosive etc. Correct data is required for correct model selection.

* Not all products' parameter are listed. For more information, please contact us by info@konmixchina.com.

Suitable to do the materials of viscosity up to 100,000 cps

Production Capacity: 0~10,000L

Applied materials: Suitable for industrial coatings, general printing inks, paint, and general pigment dispersions, cosmetic, cream, shampoo, calcium carbonate powder, liquids agrochemicals etc.