Category: Batch Homogenizer/emulsifier

Model:KZR-5L, KZR-10L, KZR-20L

Feature: Vacuum work condition, with emulsifying pot, water-phase pot&oil-phase pot.The running speed is variable rpm

This equipment mainly consists of homogenizing pot, water-phase&oil-phase pot, agitator, vacuum system,

electric heating/steam heating system with temperature control,electrical control etc.

The main pot/reactor's cover lifts up together with the homogenizer head.

This model can make top grade cosmetic, cream, pharmaceutical ointment, honey,-- etc.

• The mixing pot's cover with lifting up&fall down function.

• Machine's contacting parts are made of SS304 or SS316L stainles-steel.

• Contacting parts' surface is treated to sanitary grade.

• The materials in water-phase pot & oil-phase pot can be feeded into emulsifying pot.

• With electrical heating up function.

• Each pot/reactor can be heated by electrical heaters with conductive medium.

• The temperature can be set and automatically controlled.

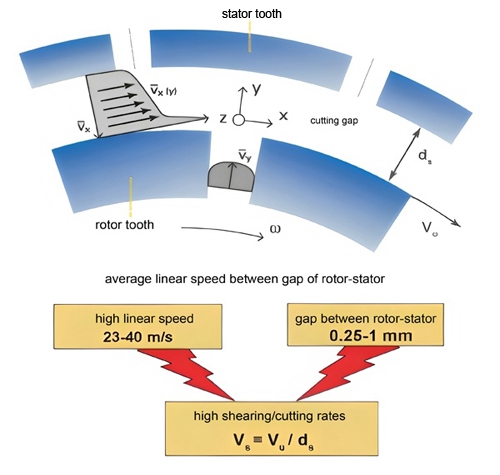

The precised stator and rotor matches with each other perfectly.

High-speed rotation motor drives the rotor to rotate at high speed, which generates vacuum condition between the stator and rotor. So materials are sucked into the chamber from the top of the stator &rotor and also from the bottom.

Rotor driven by the strong kinetic energy creates high linear speed, which puts the materials under comprehensive action of strong crushing, tearing, centrifugal extrusion, hydraulic friction etc between the precision-engineered gap of the stator and rotor.

After processed, the materials are flying out and generates strong turbulence under the action of forces from different direction.

Stable emulsion is obtained after repeated disaggregation, dispersion, homogenization, shearing for a certain period with help of mature production technology and certain quantity emulsifier.

| Model | Capacity(L) | Power(kw) | Speed(rpm) | Lifting stroke(mm) | Vacuum degree(Mpa) |

| KZR-5L | ≤5 | 0.75 | 0~2900 | 300 | -0.095 |

| KZR-10L | ≤10 | 1.1 | 0~2900 | 400 | -0.095 |

| KZR-20L | ≤20 | 1.5 | 0~2900 | 500 | -0.095 |

Remarks:

* The above listed max. capacity is calculated according to water as medium. Model selection should depend on the comprehensive factors, such as materials' viscosity, gravity etc.

* If works under special environment such as high temperature, high pressure, explosive, combustible, corrosive etc. Correct data is required for correct model selection.

* Not all products' parameter are listed. For more information, welcome to contact us by info@konmixchina.com.

Lab trials' capacity: 5L, 10L, 15L, 20L or 30Liters.

Applied materials: suitable for emulsifying, homogenizing and dispersing materials in industries, such as biology, pharmacy, food, cosmetic, ink and pesticide, honey --- etc.