Category: Sigma kneading mixer

Model:KNHE Series

Feature: This mixer is widely used in the mixing, kneading, crushing, stirring, vulcanization, re-polymerization of high viscous products, with heating function

The kneading machine is also called " sigma mixer machine ".

It is the ideal equipment for kneading, mixing, curing and polymerization of high viscosity and elastic-plastic materials.

It is often used in the production of silicone rubber, sealant, hot melt glue, food glue base, pharmaceutical preparations, etc.

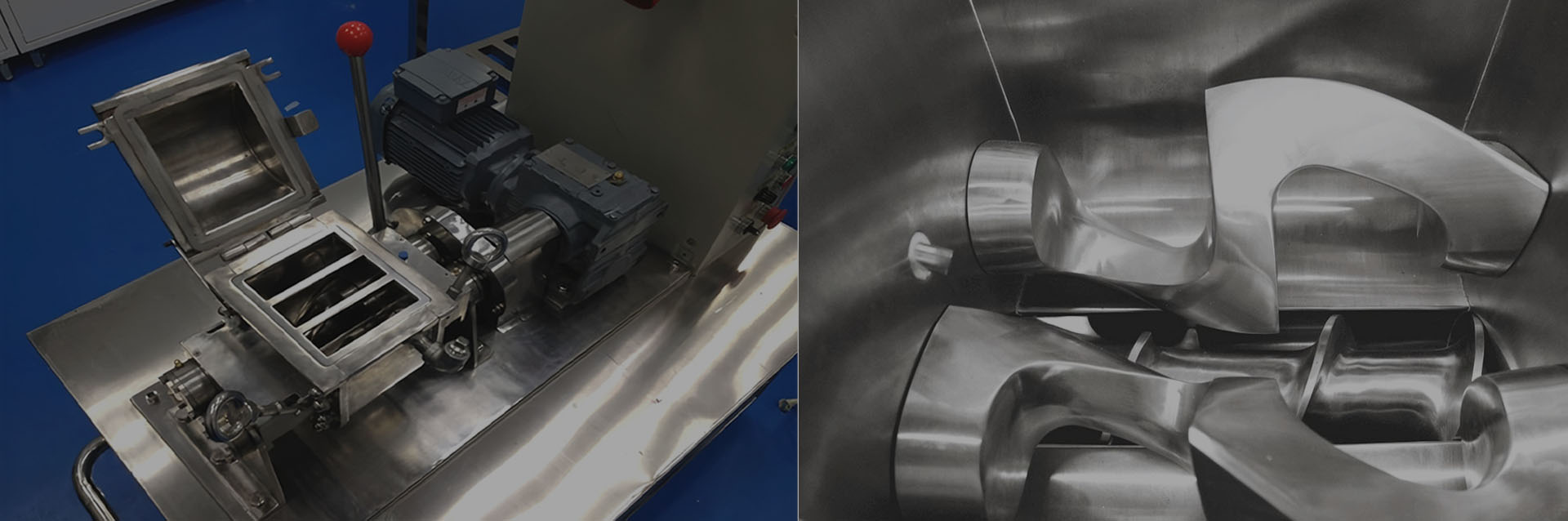

It is a special kind of mixing equipment and the most commonly used is using two sigma blades, differential side by side, namely a mixing propeller speed, a mixing propeller speed, in order to produce shear force, different paddles make mixing material can be cut quickly, so that the material can mix very well.

• This kneader generally adopts a whole chassis for easy installation.

• Using the bevel gear or hard toothed reducer to make the transmission between the main engine smooth.

• With low running noise and long working life.

• Stirring Z paddle and chamber are made of stainless-steel to ensure the purity of products.

• Advanced shaft sealing structure and good sealing effect.

• Unique design of vacuum box balance structure to ensure that no black material will be worn out.

• Integrated electrical control (main engine operation, hydraulic cylinder flipping, hydraulic lid opening and constant temperature control).

• Thismachne has the heating up function.

• The temperature control and temperature display for easy operation and process control.

The sigma kneading mixer is produced by a pair of Σ blades that cooperate and rotate to produce strong shear action, so that the semi-dry or rubber-like viscous plastic material can quickly react to obtain uniform mixing and stirring.

The kneading machine mainly consists of five major parts: the mixing section, the base section, the hydraulic system, the transmission system, and the electrical control system. The hydraulic system is operated by a hydraulic station to control the large cylinder for opening and closing functions. The hydraulic system also controls the cylinders to perform functions such as flipping the cylinder and lifting the lid. Detailed parameters can be chosen and required by the user at will, making operation convenient and reliable. The transmission system comprises an electric motor, a reducer, and gears, with the motor matched according to the model of the kneading machine.

The transmission part of the kneader is driven by the synchronous speed of the motor, which is transferred to the reducer through the elastic coupling, and then the output device drives the fast slurry to reach the specified speed, which also can be adjusted by the frequency converter.

The kneader has two Σ-shaped blades, and the speed of the two blades is different. Different speeds can be set according to different process.

| Model | Chamber(L) | Suggested feeding(L) | Main power(kw) | Discharging ways | Heating ways |

| KNH-5 | 5 | 3 | 1.5 | Manual rotation/conveyor | Electric heating |

| KNH-10 | 10 | 6 | 2.2 | Manual rotation/conveyor | Electric heating |

| KNH-50 | 50 | 30 | 4 | Manual rotation/conveyor | Electric heating |

| KNH-100 | 100 | 60 | 7.5 | Hydraulic turning/conveyor | Electric heating |

| KNHE-200 | 200 | 120 | 11 | Hydraulic turning/conveyor | Electric heating |

| KNHE-300 | 300 | 180 | 15 | Hydraulic turning/conveyor | Electric heating |

| KNHE-500 | 500 | 300 | 30 | Hydraulic turning/conveyor | Electric heating |

| KNHE-1000 | 1000 | 600 | 37~55 | Hydraulic turning/conveyor | Steam heating |

| KNHE-1500 | 1500 | 900 | 45~90 | Hydraulic turning/conveyor | Steam heating |

| KNHE-2000 | 2000 | 1200 | 55~110 | Hydraulic turning/conveyor | Steam heating |

| KNHE-3000 | 3000 | 1800 | 75~132 | Hydraulic turning/conveyor | Steam heating |

| KNHE-4000 | 4000 | 2400 | 90~160 | Hydraulic turning/conveyor | Steam heating |

Materials' viscosity up to 50,000 Pa.s;

Production capacity: 5~10,000Liter;

Applicable materials: Sigma kneading mixer is widely used in the mixing, kneading, crushing, stirring, vulcanization, re-polymerization of high viscous & high elasto-plastic materials.

This kneader has the advantages of uniform mixing, no dead corners, high kneading efficiency. It is versatile, with a wide variety of functions and applications.

It is particularly suitable for industries such as: chewing gum, bubble gum, toothpaste, plastics, rubber, silicone rubber, dyes, pigments, inks, food gums, pharmaceuticals, architectural coatings, carbon, cellulose, high-viscosity sealants, aluminum paste, silicone, pulp, cellulose, battery pastes, dyes, organic silicon resins.