Category: Vacuum emulsifying mixer

Model:KRH-V

Feature: With the vacuum work condition, mixing agitator with emulsifying mixer & scraper blade, suitable to do high viscosity products

This type vacuum homogeneous emulsifier can work under vacuum condition.

This model has customized service for users.

The workhead includes: emulsifying rotor-stator workheads, paddle agitator and scraper.

Its running speed can be controlled by frequency inverter.

It can work with water-phase pot and oil-phase pot.

• This model is usually non-standard designed and manufactured according to user's technologic request.

• It can equip low-speed scraper and match with Inline high-shear emulsifier.

• Following systems are option: dosing & discharging system, cooling/heating, temperature controlling, vacuum system.

• All components are processed by the CNC machine.

• The mixing shaft is through dynamic and static balance test to ensure the stable and safety.

• It is mainly used for high viscous materials.

• This model is widely used in industries of cosmetic, lotion, cream, honey.

Whole unit has the vacuum function in homogenious, mixing process.

Whole unit has the vacuum function in homogenious, mixing process.

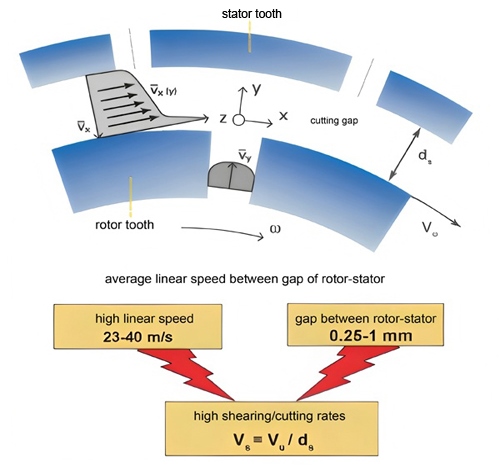

The precised stator and rotor matches with each other perfectly.

High-speed rotation motor drives the rotor to rotate at high speed, which generates vacuum condition between the stator and rotor. So materials are sucked into the chamber from the top of the stator &rotor and also from the bottom.

Rotor driven by the strong kinetic energy creates high linear speed, which puts the materials under comprehensive action of strong crushing, tearing, centrifugal extrusion, hydraulic friction etc between the precision engineered gap of the stator and rotor.

After processed, the materials are flying out and generates strong turbulence under the action of forces from different direction.

Stable emulsion is obtained after repeated disaggregation, dispersion, homogenization, shearing for a certain period with help of mature production technology and certain quantity emulsifier.

| Model | Capacity(L) | Emulsifier power(kw) | Speed(rpm) | Lifting stroke(mm) | Vacuum degree(Mpa) |

| KRH-V-30L | ≤30 | 1.5 | 0~2900 | 400 | -0.095 |

| KRH-V-50L | ≤50 | 2.2 | 0~2900 | 500 | -0.095 |

| KRH-V-100L | ≤100 | 5.5 | 0~2900 | 700 | -0.095 |

| KRH-V-200L | ≤200 | 7.5 | 0~2900 | 800 | -0.095 |

| KRH-V-300L | ≤300 | 11 | 0~2900 | 900 | -0.095 |

| KRH-V-400L | ≤400 | 15 | 0~2900 | 1000 | -0.095 |

| KRH-V-500L | ≤500 | 22 | 0~2900 | 1100 | -0.095 |

| KRH-V-1000L | ≤1000 | 30 | 0~2900 | 1200 | -0.095 |

| KRH-V-1500L | ≤1500 | 37 | 0~2900 | 1300 | -0.095 |

Remarks:

* The above listed max. capacity is calculated according to water as medium. Model selection should depend on the comprehensive factors, such as materials' viscosity, gravity etc.

* If works under special environment such as high temperature, high pressure, explosive, combustible, corrosive etc. Correct data is required for correct model selection.

* Not all products' parameter are listed. For more information, welcome to contact us by info@konmixchina.com.

Materials' viscosity up to 1,000 Pa.s

Production capacity: 0~1500L with lifting up stand; if the stationary reactor/pot style, then capacity up to 8000Liters.

Applied materials: suitable for emulsifying, homogenizing and dispersing materials in industries, such as biology, pharmacy, food, cosmetic, ink, honey, cream, and pesticides etc.