Konmix Corporation

+86-21-60546980

+86-21-60546980

No.2601,Xietu Rd,Shanghai

No.2601,Xietu Rd,Shanghai

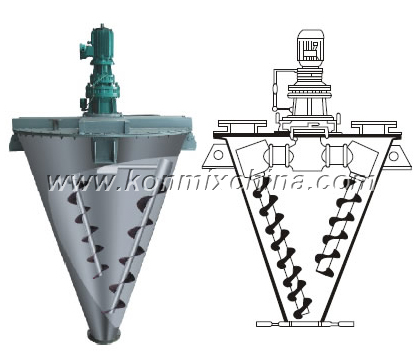

Name: Conical Screw Mixer

Category: Powder Mixers

Model: KMSZ

Feature: This mixer consists of a conical shape chamber, top driving unit and screw agitators, with large batch capacity

Overview

This mixer is also famous known as " Nauta Mixer ".

It has reasonable design and with higher speed mixing, low power consumption.

It is convenient for operation, clearance & maintenance.

Part of the chamber's lid/cover can be opened in order to clean easily.

Two dissymmetric helixes with rapidl running in clockwise direction and agitate materials upward.

Workhead will revolve along the cylinder wall slowly in order that materials can be mixed at all directions to achieve high-degree mixture in short time.

Design Highlights

• The distinctive design especially the wide door can facilitate unloading with high speed and no remnant.

• The rapid rotating of the double helixes will rise inside materials and generate two dissymmetrical spiral material

flows alongside the chamber’s wall from downward to upward.

• Running screw caused by main arm can get materials to different degree moving along with helix.

• Some materials are uplifted and others are thrown away, and all materials blendeded well.

• Because of the compound movement above, the material can be mix with more balance and precision.

Working Principle

Double screw conical mixer rotated around its axes by right of two internal asymmetric spirals which is installed on the cantilever. Mean while, the rotational force from the cantilever drive two spiral doing revolution around conical chamber

axle wire.

Double screw conical mixer has 4 direction forces:

a. Two inner asymmetric spiral upgrade materials by rotation.

b. Tumbler low-speed rotation makes material circle motion.

c. Spiral rotation and revolution make materials absorbed while diffuse to circle direction.

d. Two flow materials upward then down to center, which come into being a downward material flow.

e. This way can full the bottom gap and form a convective circulation.

Technical Parameter

|

Model |

Motor |

Speed |

Capacity |

Shape Size |

Weight |

|

KMSZ-0.5 |

3 |

2/108 |

150-300 |

Φ1140*2320 |

620 |

|

KMSZ-1 |

4 |

2/57 |

300-600 |

Φ1480*2895 |

1200 |

|

KMSZ-2 |

5.5 |

2/57 |

600-1200 |

Φ1816*3495 |

1500 |

|

KMSZ-3 |

7.5 |

1.8/57 |

900-1800 |

Φ2040*3760 |

2350 |

|

KMSZ-4 |

11 |

1.6/54 |

1200-2400 |

Φ2250*4430 |

2530 |

|

KMSZ-5 |

15 |

1.3/50 |

1500-3000 |

Φ2370*4700 |

2800 |

|

KMSZ-6 |

15 |

1.3/50 |

1800-3600 |

Φ2548*4950 |

3000 |

|

KMSZ-8 |

18.5 |

1.3/50 |

2400-4800 |

Φ2780*5360 |

4500 |

|

KMSZ-10 |

22 |

1.3/50 |

3000-6000 |

Φ3020*5815 |

5500 |

Remarks:

* The above listed data is calculated according to powder’s gravity of 1.0g/cm3 as medium. Model selection should depend on the

comprehensive factors, such as viscosity, mesh, gravity etc.

* If works under special environment, such as high temperature, high pressure, explosive, combustible, corrosive etc. Users need to provide

detailed data, in order to select and customize.

* Not all products’ parameter are listed. For more information, please contact our sales engineer by info@konmixchina.com

Product Application

It is widely used in stirring and mixing powder and powder, such as pharmaceutical, food, chemical, pesticide, dyestuff, battery material, rare earth, sand, mortar and other industries.