Konmix Corporation

+86-21-60546980

+86-21-60546980

No.2601,Xietu Rd,Shanghai

No.2601,Xietu Rd,Shanghai

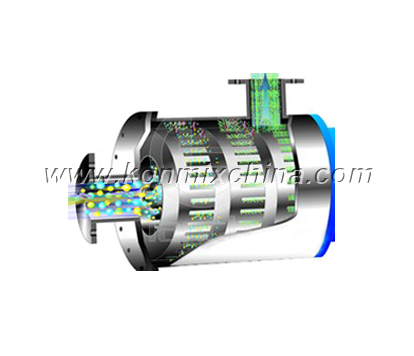

Name: In-line Homogenizer (3-stage chamber)

Category: Inline homogenizer pump

Model: KRB/3

Feature: In-line high shear homogenizing, 3-stage chamber, with much more layers rotor & stator head, finer high shearing function

Overview

This In-line homogenizer is also called “ Inline high-shear homogenizing pump ”.

It works in continuous production or circulation of fluid materials.

Its work-chamber consists of three(3) stage/group structure, with much more layers rotor & stator workhead.

The strong centrifugal-force absorbs materials into the working chamber from axial direction.

All the materials are highly sheared & homogenized by multi-layers rotors & stators.

Design Highlights

• With different powers for optional.

• Users can select with various running speed control.

• The contacting parts can be made in SS304 or SS316L stainless steel.

• Work style: Inline high-shearing.

• Three stages rotor/stator workhead, first stage is 1-layer rotor & stator, second stage is 2-layers,

third stage is 3-layers rotor & stator.

• Favored temperature -20<200℃.

• The chamber can be made with jacket for cooling or heating up.

• Stable products are produced after one time or a few times circulation.

Working Principle

This inline homogenizer (three-stage type) is circulation workings, there are a few layers stator and rotor in the chamber.

The stator & rotor is double coupling design with high matching precision.

The central shaft driven by the motor rotating at a high speed vacuumizes the gap of the rotor and stator, which suck

the materials into the stator and rotor chamber. Rotor driven by the strong kinetic energy creates high linear speed,

which puts the materials under comprehensive action of strong crushing, tearing, centrifugal extrusion, hydraulic

friction etc between the precision-engineered gap of the stator and rotor.

After processing, the materials are flying out and generates strong turbulence under the action of forces from

different direction.

Technical Parameter

|

Model |

Power (kw) |

Flow |

Speed |

Inlet |

Outlet |

|

KRB 4/3 |

4 |

4 |

2880 |

DN40 |

DN32 |

|

KRB 7.5/3 |

7.5 |

8 |

2880 |

DN40 |

DN32 |

|

KRB 11/3 |

11 |

12 |

2880 |

DN50 |

DN50 |

|

KRB 18.5/3 |

18.5 |

16 |

2880 |

DN65 |

DN50 |

|

KRB 22/3 |

22 |

18 |

2880 |

DN80 |

DN65 |

|

KRB 30/3 |

30 |

25 |

1440 |

DN100 |

DN80 |

|

KRB 37/3 |

37 |

30 |

1440 |

DN100 |

DN100 |

|

KRB 45/3 |

45 |

40 |

1440 |

DN125 |

DN100 |

|

KRB 55/3 |

55 |

50 |

1440 |

DN125 |

DN100 |

|

KRB 75/3 |

75 |

60 |

1440 |

DN150 |

DN125 |

|

KRB 90/3 |

90 |

70 |

1440 |

DN150 |

DN125 |

|

KRB 110/3 |

110 |

80 |

1440 |

DN150 |

DN125 |

Remarks:

* The above listed max. capacity is calculated according to water as medium. Model selection should depend on the comprehensive factors,

such as materials' viscosity,gravity etc.

* If works under special environment such as high temperature, high pressure, explosive, combustible, corrosive etc. Correct data is required

for correct model selection.

* Not all products’ parameter are listed. For more information, please contact us by info@konmixchina.com.

Product Application

This machine is suitable to do the materials of viscosity up to 100,000 cps.

Production capacity scope: 0~10,000L.

Applied materials: Suitable for industrial coatings, general printing inks, paint, and general pigment dispersions, cosmetic, adhesive, ointment, cream, shampoo, calcium carbonate powder, liquids agrochemicals etc.